SDF-3.5 500 x 1000 60 TPH 1000 watts SDF-4.5 750 x 1100 100 TPH 1500 watts SDF-5.5 900 x 1500 150 TPH 2100 watts SDF-6.5 900 x 1500 200 TPH 2800 watts Vibro Feeder Technical

Syntron® Vibrating Feeders are sub-resonant tuned, two-mass, spring-connected systems . These features enable Syntron® feeders to work consistently under material damping and

Advantage Series feeders can be found on many of the Cedarapids crushing plants, bringing the benefits of the rugged construction, large stroke vibrator and adjustable

We manufacture feeders up to 200 TPH capacity for all types of free flowing materials and feed rate can be controlled from zero to maximum stepless by variac/thyristor based controller. More than 1000 vibratory feeders of various

The Vibratory Feeder assembly is a dynamically balanced, two-mass vibrating system consisting of a trough and trough mounting member coupled to the electromechanical drive by means of stacked rubber and alloy spring assemblies.

Vibratory feeders are basically applied to a control function to meter or control the flow of material from a hopper, bin, or stockpile, much the same as an orifice or valve control flow in a hydraulic system. In a similar sense, feeders can be

Feeders and conveyors transfer their drive’s natural vibration to the tray either through a single mass or two mass system. Single-mass units are anchored in position (usually to the floor)

Electromechanical feeder specification, electromechanical feeder design, Heavy Duty ElectroMechanical Vibrating Manufacturer, Supplier in India, USA and UK.

SDF-3.5 500 x 1000 60 TPH 1000 watts SDF-4.5 750 x 1100 100 TPH 1500 watts SDF-5.5 900 x 1500 150 TPH 2100 watts SDF-6.5 900 x 1500 200 TPH 2800 watts Vibro Feeder Technical Specifications (Suspension Mounted Design) Model Tray Size in mm Power consumption Capacity per hour (for material with density 1500 kg/m3) SDF-3 300 x 900 25 TPH 350 watts

The Vibratory Feeder assembly is a dynamically balanced, two-mass vibrating system consisting of a trough and trough mounting member coupled to the electromechanical drive by means of stacked rubber and alloy spring assemblies.

Vibrofeeders. BAS Electromagnetic or vibratory feeders (vibro feeders / vibrating feeder) have capacities from 0.1 to 1,000 tph with equal and linear power across the entire width of the feeder surface.

Syntron® Vibrating Feeders are sub-resonant tuned, two-mass, spring-connected systems . These features enable Syntron® feeders to work consistently under material damping and other varying headload conditions with negligible changes in trough stroke . Sub-resonant tuning maintains stroke consistency and

More than 1000 vibratory feeders of various capacities, manufactured by us, are working in cement, paper, fertilizer, sugar and chemical plants all over India and abroad. They are also used in husk, wood chip fired boilers.

Electromechanical feeder specification, electromechanical feeder design, Heavy Duty ElectroMechanical Vibrating Manufacturer, Supplier in India, USA and UK.

Simple design and flexible control account for the efficient, economical performance of Syntron ® volumetric feeder machines, and the growing industrial preference for them. These units can feed most dry bulk materials and can be

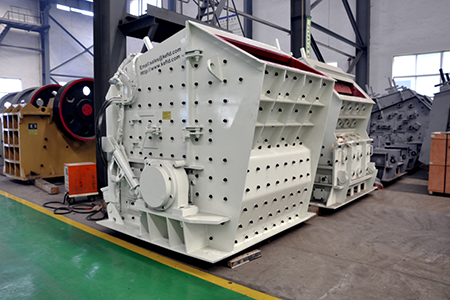

2 TPH Vibro Feeder Get Quote. Vertical Shaft Impact Crusher100TPH Get Quote. 30"x10" (750x250mm) Secondary Jaw Crushers Get Quote. Primary Jaw Crusher 48"x36" Get Quote. Cone Crusher Get Quote. SC-900mmx6000mm long

Vibro Feeder: Model Name: Feed Opening (Width mm x Breath mm) Max. Feed Size (mm) Input Capacity (TPH) Power (HP) MAX VF 800 x 1800 – 01: 800 x 1800: 180

2023年3月24日 Vibrating Feeder Control Application. A common example of feeder control is when it discharges into a multihead weighing system. Since the multihead weigher can only handle a certain amount of product at a time, the feeder must stop when the input exceeds this limit. Sensors on the multihead weigher detect when the product level is too high.

Ecoman 400 TPH Vibrating Feeder ₹17,00,000. Voltage. 220 V. Phase. Single. Brand. Ecoman. Capacity (TPH) 400. Length. 1800 mm. Width. 1200 mm. ... Flour electromagnetic vibro feeder, for industrial, lifting ... Vibrating feeder; Cast iron single phase electro magnetic vibrating feeder; Bowl Vibratory Feeder

A vibratory feeder is an instrument that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, ...

Manufacturer of Vibrating Feeder - Motorized Vibro Feeder offered by Midas Autosoft Engineers Private Limited, Pune, Maharashtra. Midas Autosoft Engineers Private Limited. Warje, Pune, Maharashtra GST No. 27AAECM2414R1Z5. ... 5TPH TO 200 TPH: Usage/Application: Industrial: Voltage: 415: Phase: 3:

2012年5月4日 The feeder used a concentrated sub resonant design to mimic a full sized sub resonant feeder. ... Capacity (tph) 5: Tags: Iron Ore, Mining, Vibrating Feeder. Read more articles. Previous Post Granite Vibratory Screen. Next Post Screen Feed

Remote access, multiple program feature and continuous feedback loop puts the SPIROL Mark VI Controller with Series 2000 High Performance Feed System on the leading edge in feeder technology. The Mark VI Controller is a state-of-the-art, microprocessor-based controller for use with SPIROL Series 2000 High Performance Feed Systems.

The currently available price/cost of the Deepa 30 HP Heavy Duty Vibro Feeder, For Industrial, Lifting Capacity: 13 TPH on our AAJJO platform is ₹1800000.00. For more accurate pricing, please request the quotation from the sellers by clicking on the “request callback” button on the Deepa 30 HP Heavy Duty Vibro Feeder, For Industrial, Lifting Capacity: 13 TPH detail page,

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال