The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for

The four most common types of coal pulverizers are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on

2017年6月2日 Ball mills use a tumbling process with stone or metal balls as the grinding materials to reduce the coarse material by means of impact and

Coal pulverizers may be classified by speed, as follows: • Low Speed• Medium Speed• High SpeedA ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in l

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch.

We design and build new ball mill pulverizers including: pebble mills, jar mills, sand mills, and SW mills. We also service all types of mills, provide on-site alignment, gear installation, and reline

China Ball Pulverizer wholesale - Select 2024 high quality Ball Pulverizer products in best price from certified Chinese Grinding Equipment manufacturers, China Mills suppliers, wholesalers

China Ball Mill Pulverizer wholesale - Select 2024 high quality Ball Mill Pulverizer products in best price from certified Chinese Rice Mill manufacturers, Metal Ball suppliers, wholesalers and

A ball mill pulverizing system is a typical strongly coupled multi-input multi-output (MIMO) plant, which is also nonlinear and widely used in coal-fired power

Learn about the types and operation of pulverisers used to crush coal in thermal power plants. Bowl mill and ball mill are two common examples of medium speed mills for sub-bituminous to anthracite coals.

2017年6月2日 Learn about the types, uses and principles of crushers, grinding mills and pulverizers, which are machines that reduce the size of coarse

Industrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, primarily used for grinding and blending materials to achieve uniform consistency and fine particle sizes. These machines are

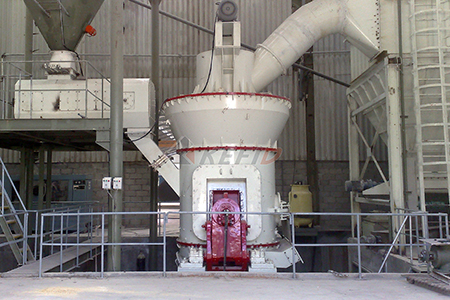

Bradley Airswept Roller Mills provide a highly efficient and effective system for pulverizing, crushing, and grinding a wide variety of materials. Resources; Videos; ... The unique over-driven design of the Bradley Pulverizer Air Swept Mill is more efficient than other mills resulting in a lower per ton operating cost.

Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer. Ring-Roll and Ball-Race. Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs. One or both of the races may rotate against a ball or roll (in a Ring-Roll Mill, the rolls may rotate while the ring is stationary).

RETSCH laboratory pulverizer mills utilize various mechanisms, including pressure, friction, and impact, ... Typical pulverizers for fine grinding are disc mills, ball mills and rotor mills. Depending on the application and desired throughput, continuous or batch processing may be advantageous and will determine the choice of pulverizer.

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. BW's pulverizers, found at power stations throughout the world.

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the

Disc Mill Pulverizer merupakan salah satu dari rangkaian alat preparasi sampel yang berfungsi untuk menghaluskan (pulverizing) sampel dengan tingkat kehalusan mulai dari mesh 150 atau 89 micron (μm) hingga 200 mesh atau 75 micron (μm).Secara fungsi, disc mill pulverizer memiliki kemiripan dengan lab pulverizer yaitu sama-sama menghaluskan material sampel.

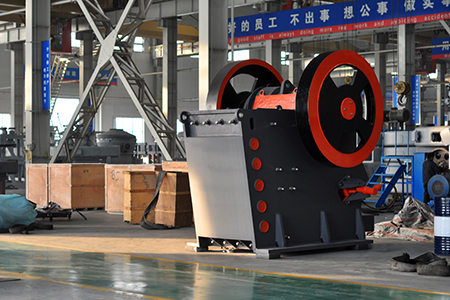

Bico Braun International, Jaw Crusher, Assay Lab Equipment, Pulverizer, Ball Mill, Furnace,Oil Centrifuge, Jaw Crusher, Chipmunk,Badger Crusher, Mining, Vibratory ...

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch.

Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer. Ring-Roll and Ball-Race Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs. One or both of the races may rotate against a ball or roll (in a Ring-Roll Mill the rolls may rotate while the ring is stationary).

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال