2024年7月31日 It was found that, when only 10 mm balls were used, large particle size was not reduced, and the grinding process time increased. It was reported that maximum energy efficiency was achieved when 10 and 20 mm balls were used together in fine-grained feeds.

Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall. Organic compounds are also often added as grinding aids to avoid powder agglomeration. Triethanolamine (TEA) is commonly used at 0.1 wt. % and has proved to be very effective. Othe

2022年4月20日 In cement manufacturing, forged steel grinding balls are used to grind clinker, the key ingredient in cement production, along with other raw materials like limestone, gypsum, and fly ash. These materials must be

Clinker Grinding: Mill balls are used in cement plants to grind clinker, which is a key ingredient in cement production. The grinding process converts clinker into fine cement powder. 3.

2023年10月23日 In this study we compare the effects of three different grinding aids on clinker grinding using a ball mill. A commercial grinding additive, triethanolamine (TEA), and two industrial...

2024年2月22日 The robustness and superior impact strength of steel balls make them ideal for breaking down hard materials like metals and minerals. In cement manufacturing, steel balls are used in large quantities for the grinding of

2023年5月10日 Grinding balls are an essential component of many industrial processes, including mining, cement production, and ore processing. They are used to grind materials into

this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in clinker grinding, the

2024年7月31日 It was found that, when only 10 mm balls were used, large particle size was not reduced, and the grinding process time increased. It was reported that maximum energy efficiency was achieved when 10 and 20 mm balls were used together in fine-grained feeds.

Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall. Organic compounds are also often added as grinding aids to avoid powder agglomeration. Triethanolamine (TEA) is commonly used at 0.1 wt. % and has proved to be very effective. Othe

2023年10月23日 In this study we compare the effects of three different grinding aids on clinker grinding using a ball mill. A commercial grinding additive, triethanolamine (TEA), and two industrial...

100mm balls. The use of 100mm balls is possible, but should be avoided as wear and liner damages will increase. In this case, the usage of 60mm balls should be reduced to a minimum. Big balls climb to the highest position à increased

The present article deals with the wear of the balls used for the grinding of the clinker in the processes of obtaining cement. Three specimens of different steel were made: one of steel...

Clinker Grinding: Mill balls are used in cement plants to grind clinker, which is a key ingredient in cement production. The grinding process converts clinker into fine cement powder. 3.

2024年2月22日 The robustness and superior impact strength of steel balls make them ideal for breaking down hard materials like metals and minerals. In cement manufacturing, steel balls are used in large quantities for the grinding of

this paper, the method was used to study the collisions between grinding media and grinding media and walls in ball mills, which is the most used unit operation in clinker grinding, the

2022年4月20日 The size of the grinding balls should match the specifications of your ball mill and the nature of the material being ground. Smaller balls are typically used for fine grinding, while larger balls are more suitable for

2020年7月24日 This paper presents results regarding the grinding behaviour of two batches of material (clinker) in a ball mill with its own two-step grinding process: the first one with a ball load, the second ...

2023年10月23日 In this study we compare the effects of three different grinding aids on clinker grinding using a ball mill. A commercial grinding additive, triethanolamine (TEA), ...

(Fig. 1). The grinding media used were steel spheres of 35 mm diameter, with density and bed voidage in values of 7890 kg/m3 and 0.368. The clinker used in the grinding Fig. 1 Experimental module used in the tests and interior of the mill

Table 1. Chemical composition of typical grinding media (% wt.). Adapted from [24]. 2.1.1. Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in ...

2020年7月16日 The detailed deformation mechanism and its microstructural modifications of white cast iron grinding balls used in comminution have been investigated using transmission electron microscopy (TEM) and XRD. De-shaping is the primary mode of ball consumption, and fracture of balls is a relatively uncommon failure mode. Deshaping is the manifestation of

Portland clinker is the main constituent of most cements. In Portland cement, a little calcium sulfate (typically 3-10%) is added in order to retard the hydration of tricalcium aluminate.The calcium sulfate may consist of natural gypsum, anhydrite, or synthetic wastes such as flue-gas desulfurization gypsum. In addition, up to 5% calcium carbonate and up to 1% of other

2015年1月27日 The use of high-pressure grinding rolls (HPGR) prior to ball mills has become a common practice in cement clinker grinding due to significant energy savings in comparison to ball milling alone.

Grinding ball Allmax I ® (11-13% chromium content) is particularly suitable for cement grinding (raw material and clinker), in particular in the 2nd and 3rd chamber of a tube mill for cement and raw meal grinding; Grinding ball Allmax II ® (17-19% chromium content and higher) is particularly suitable for use in the 1st grinding chamber of a ...

2024年7月31日 The production of cement, an essential material in civil engineering, requires a substantial energy input, with a significant portion of this energy consumed during the grinding stage. This study addresses the gap in the literature concerning the collective impact of key parameters, including ball size, feed rate, and mill speed, on grinding efficiency. Nine

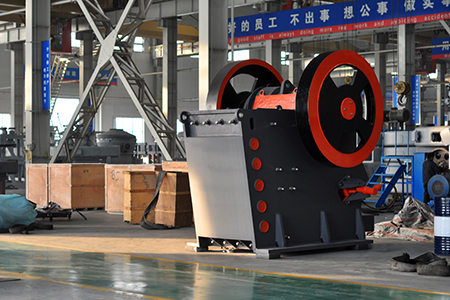

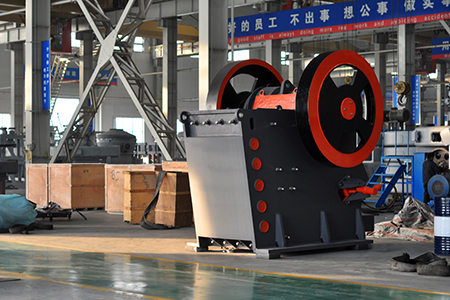

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال